Configure your label

Industrial

Industrial

Durable, printable labels for what matters in your industry

What type of label is it?

Asset ID and Inventory Labels

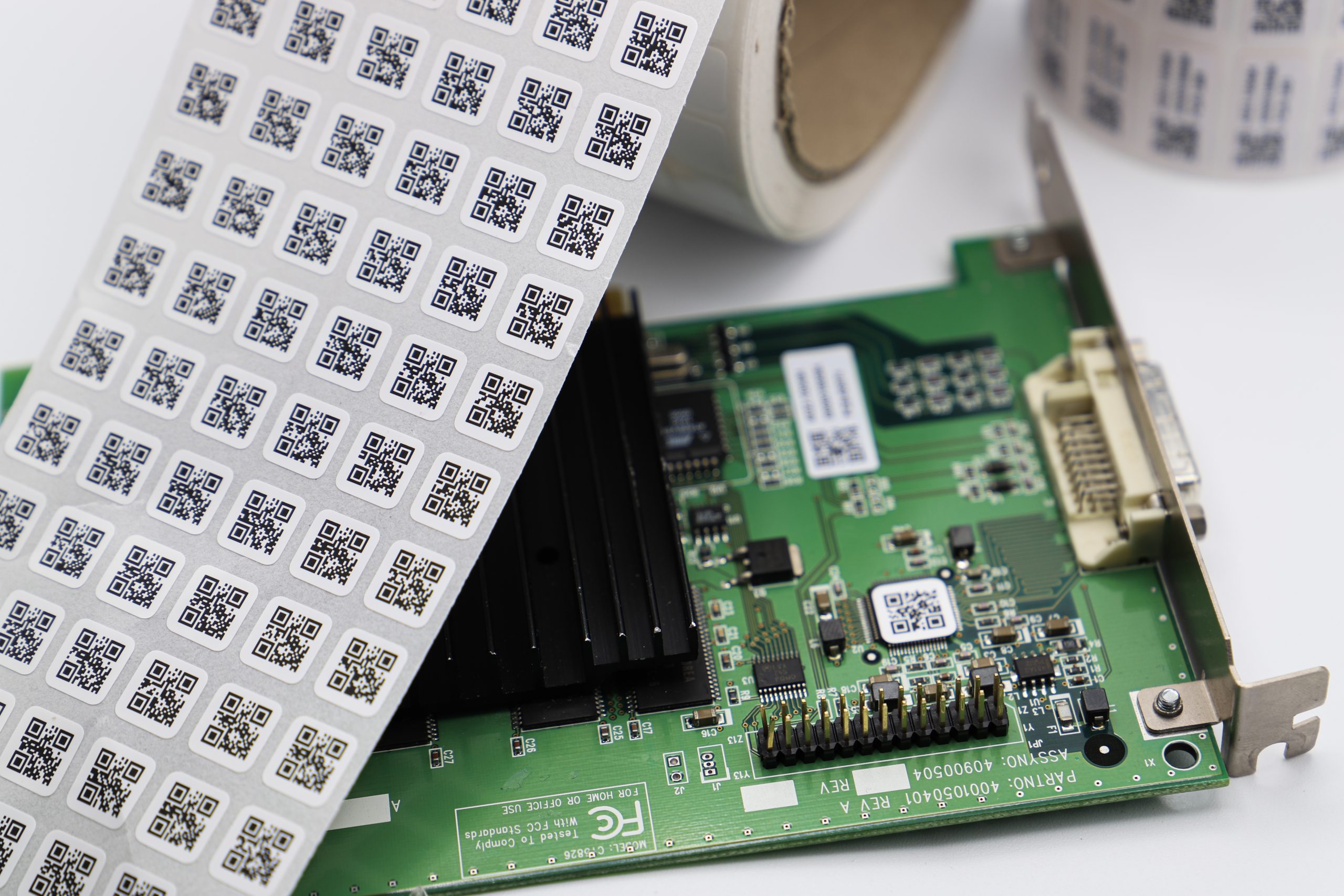

Barcode and Serial Number Labels

Branding and Product Identification Labels

Cable Identification Labels

Calibration Labels

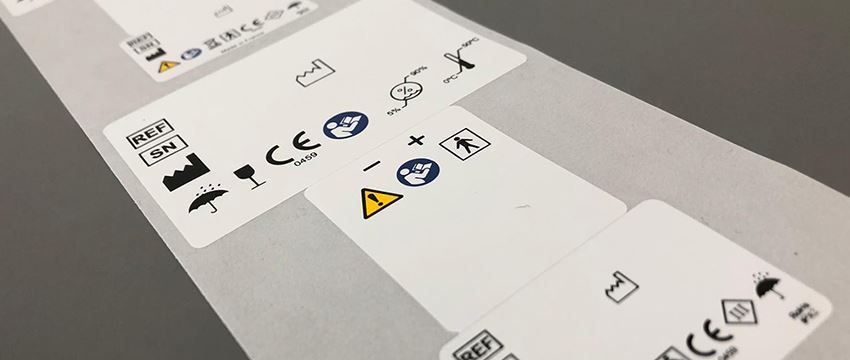

Compliance Labels

Component Labels

Hose and Pipe ID Labels

PCB Identification and Tracking Labels

Rating Plate Labels

Sign and Seal Labels

Tamper-Evident Security Labels and Seals

Temporary Removable Labels

UL Labels

Warning, Safety and Instruction Labels

Laboratory

Laboratory

Durable, printable labels for what matters in your laboratory

What type of label is it?

Asset ID and Inventory Labels

Barcode and Lot Number Traceability Labels

Blockout Masking Labels

Branding and Pharmaceutical Product ID Labels

Cap and Tube Labels

Cold and Cryogenic Labels

GHS, Warning and Instruction Labels

Label Sets for Clinical Studies and Trials

Labware Labels

Microscope Slide Labels

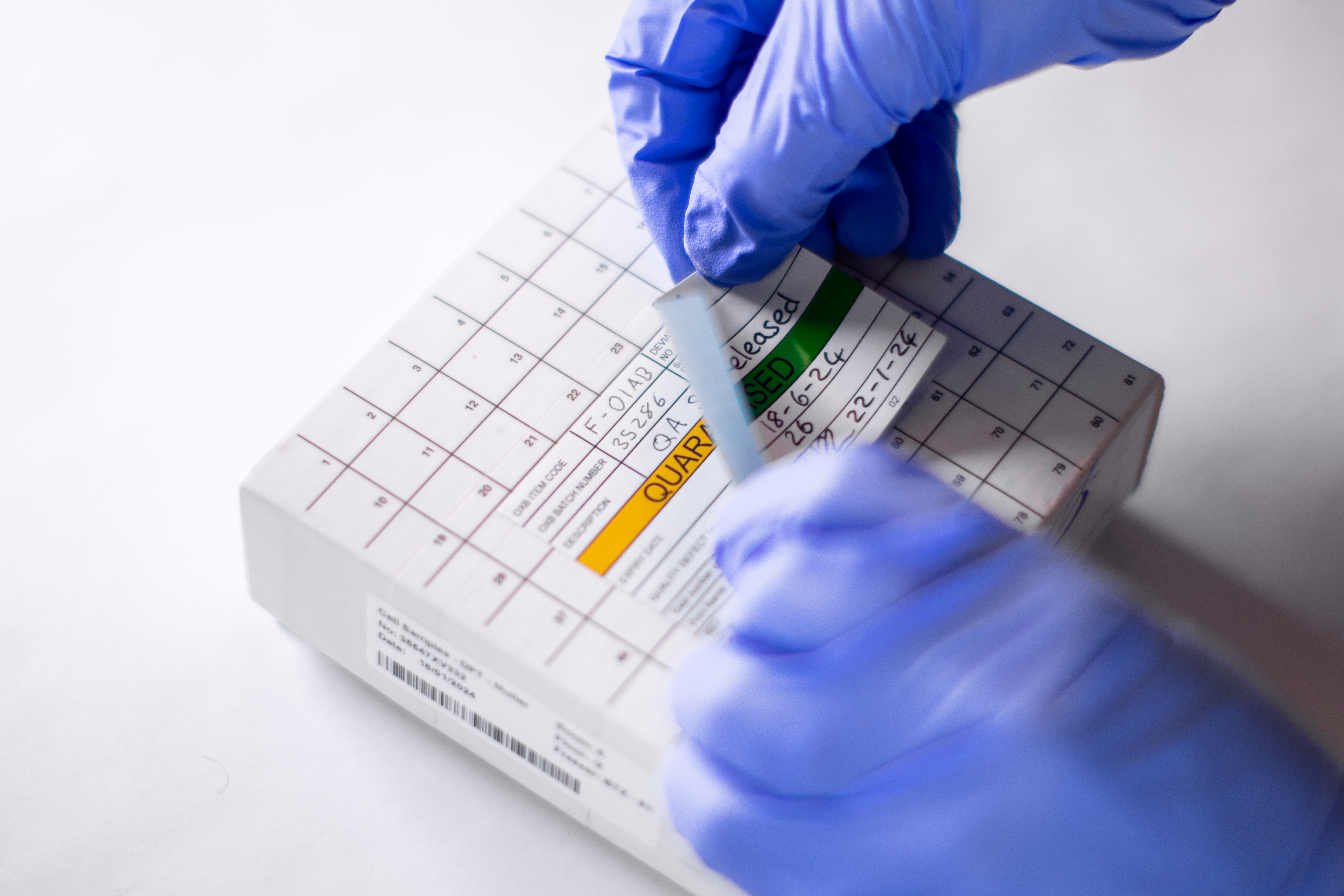

Quality Control and Quarantine Labels

Sample Identification Labels

Sterilisation Indicator Labels

Tamper-Evident Security Labels and Seals

Temporary Removable Labels

About

About

Who we are, what we do, how to join

Samples

Need a sample?

No problem.

No problem.

We're happy to provide samples free of charge.

Try them on your application, and our team will make sure their specification is perfect for your need.

Repeat orders

Our team makes ordering

as easy as possible.

as easy as possible.

Don't worry. We keep comprehensive archives as part of our commitment to complete customer care!

Place an order

Submit your requirements

Contact us

Contact our team

About

French

French

German

German

US English

US English