Durable Industrial Barcode Labeling: The Basics

Bar codes have revolutionized the industrial environment, from the way we manage assets and inventory, to helping us create streamlined, automated production processes. Bar code labels can be applied to virtually any surface, hugely increasing the speed and accuracy of tracking and identifying machinery, equipment and components either temporarily or permanently.

What are bar codes?

Bar codes are specific patterns that contain information about the items they’re attached to. These patterns can be in a range of formats; either a series of parallel lines (linear bar codes), or in a grid of squares, triangles, dots or hexagons (2D bar codes). When the stored data is required, a scanner or imager can be used to “read” the patterns, and relay the decoded contents back to your computer system. Bar coding is one method of AIDC, “automatic identification and data capture”, or “Auto ID”.

Hose labels with linear bar codes and human-readable element

Why should I use durable bar code labels?

Using AIDC with properly printed bar codes will significantly increase your productivity while lowering business costs, particularly compared to manual data-logging processes. After all, computers don’t get tired, distracted or need coffee breaks! The risk of typos, illegible handwriting and mis-reading data is virtually eliminated, allowing for fewer interruptions to your production lines, more accurate equipment monitoring and reliable asset management.

In the harshest conditions, bar codes on the correctly matched durable label won’t fade, smudge or become unstuck – including use in infrared ovens, constant handling, solvent exposure (toluene, acetone, MEK etc.) or in outdoor environments.

What kind of bar code labels should I use?

The first step is considering the amount of space you have for a label, and how much data it’s critical to include. You should also check your industry regulations or best-practices guides. Lastly, when choosing the specific label material, make sure you know exactly what your bar code will need to stick to and the conditions it will need to withstand.

Generally favored by the automotive and defense industries, Code 39 supports the characters A-Z, 0-9 and punctuation symbols: -, ., $, /, +, % and ‘space’. Due to its low density format, it’s recommended for storing relatively low amounts of data, but is readable by nearly all bar code scanners.

The Code 128 symbology is one of the most common bar code types, due to its compact size and ability to support all 128 ASCII characters. They are particularly prevalent for bar code labels in the transportation and logistics industries.

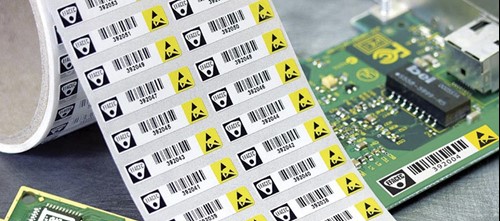

Often found on electronic component labels, Code 93 bar codes work in a similar way to Code 39 but with a more condensed symbology allowing for more data in a given area. They are sometimes used to provide complementary data to that which is stored in a corresponding Code 39 bar code.

2D bar code labels can offer the most data-per-inch, and are designed for fast but accurate scanning and decoding. They are particularly useful when space is at an absolute premium, which is the reason they are usually chosen for small-scale electronic component labeling (such as printed circuit board assembly). If necessary, the 2D codes can be paired with a corresponding linear bar code or human-readable label, for areas where space is at less of a premium. The Datamatrix and QR code formats are most popular - a Datamatrix symbol can hold up to 2,335 alphanumeric characters. However, 2D codes will require a more sophisticated imager, rather than the laser scanner used for linear codes.

How do I start bar coding my equipment and products?

If you already have access to a quality thermal transfer printer and a good label design software (such as NiceLabel), then printing in-house may be an economical option. However, you may save a lot of time (and frustration) by outsourcing your label printing, which also saves the investment into a printing system if you don’t already have one in place. That, combined with the convenience of receiving quality-tested, ready-to-use durable labels, makes it an option worth considering.

PCB labels with linear and 2D bar codes

Remember, a crisp, sharp barcode is the key to effective scanning, so if you choose to print your labels in-house, keep the following in mind:

- Providing the printer ribbon is correctly matched to your label, thermal transfer printing may offer a more durable bar code than laser printing.

- Printing at 300dpi or greater will ensure the sharpest barcodes, particularly at small sizes.

- Low-contrast printing, or voids in the print may impair the readability of your barcode. Make sure your printer is properly maintained to prevent this.

- Consider including a human-readable element as a back-up in case scanning fails.

Linear bar codes used for asset management

Bar code labels are a hugely beneficial tool for monitoring assets and equipment, tracking production processes and identifying products and components throughout their lifetime – ultimately reducing the risk and cost of human error.

To find out how easy it is to switch to bar coding, or how to improve the bar code labeling system you already have in place, contact the CILS Technical Setup Service on +1 877-512-8763, via email or fill out a contact form. Our labeling experts will be happy to help with any queries about durable labels, pre-printed labels, software or thermal transfer printing.