Bar code Labeling: The Basics

The introduction of barcoding and automatic identification and data capture (AIDC) has revolutionized the way we identify, track and trace inventory in every environment – and the clinical laboratory is no exception. Bar code labels can be applied to virtually any surface exponentially increasing the speed and reliability of cataloging chemicals, specimens, samples and patients.

What is a bar code?

A bar code is simply a computer-readable pattern that contains data about the item it’s attached to. It may be a linear bar code, where information is formatted in a series of parallel lines, or a 2D code that uses a grid of squares, rectangles, dots or hexagons. In either case, when that information is required, the markings - and the gaps between them – can be “read” by a scanner or imager and the data relayed back to your computer system, decoded.

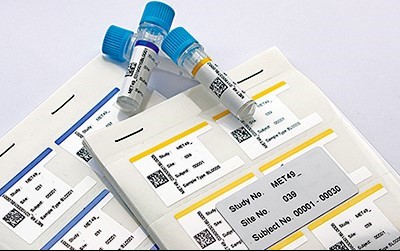

Clinical trial booklets with 2D data matrix codes

Why should I use durable bar code labels in my laboratory?

Automating your processes with bar code labels exponentially increases productivity; speeding up your data-logging and greatly reducing the risk of error caused by poor handwriting or mis-reading data.

Unlike handwriting, bar codes printed on the correctly selected label won’t fade or smudge during challenging laboratory processes – water baths, handling and rubbing, alcohol wipes and solvent exposure. A durable label material will also keep data securely attached to microslides, blood tubes, microvials etc. through long-term freezer storage and cold transit (where most labels typically fall off).

What kind of bar code and label should I use?

The first step is considering the amount of space you have for a label, and how much data it’s critical to include. If your media is particularly small (such as a microvial or centrifuge tube), you may want to consider a “cap and tube” label pair. A 2D code on the lid allows quick scanning (the tube doesn’t need to leave its rack), with additional information stuck to the side of the vessel on a larger label.

The most popular symbology for linear laboratory bar codes is Code 128, as its high-density format can store a lot of alphanumeric data in a relatively small space. Code 128 is also specified in ISO/IEC 15417:2007 for laboratories adhering to those standards.

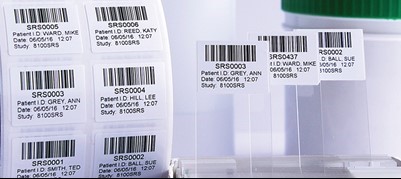

A linear barcode - Code 128 symbology

2D bar codes are ideal for when space is really at a premium, and the data matrix or QR code format is often chosen – a data matrix symbol can hold up to 2,335 alphanumeric characters. These do require a more sophisticated scanner to read, however.

A 2D code - QR code symbology

How do I start bar coding my samples and specimens?

If you already have access to label design software and a quality thermal transfer printer (highly recommended for bar code durability) then printing in-house may be an economical option. However, outsourcing your label printing can save a lot of time (and frustration), and saves the investment in a printing system if you don’t already have one in place. That, combined with the convenience of receiving quality-tested, ready-to-use durable labels, makes it an option worth considering.

Microvials with cap and tube labels

Remember, clarity is the key to a scanner reading a bar code quickly so if you choose to print your labels in-house, keep the following in mind:

- Thermal transfer printing may offer greater durability than laser printing – as long at the label material and printer ribbon are correctly matched.

- Printing at 300dpi or greater will ensure sharp bar codes, particularly at small sizes.

- Low-contrast printing, or voids in the print may impair the readability of your bar code. Make sure your printer is properly maintained to prevent this.

- Consider including a human-readable element as a back-up in case scanning fails.

Linear bar codes on microslides

Bar code labels are a hugely beneficial tool for monitoring assets and equipment, tracking production processes and identifying products and components throughout their lifetime – ultimately reducing the risk and cost of human error.

To find out how easy it is to switch to bar coding, or how to improve the barcode labeling system you already have in place, contact the CILS Technical Setup Service on +1 877-512-8763, via email or fill out a contact form. Our labeling experts will be happy to help with any queries about durable labels, pre-printed labels, software or thermal transfer printing.