Why you should pick durable printable labels over metal plates

The need for durable and dependable industrial product identification has become even more important in recent years as industrial environments and processes grow in complexity and new regulations, and compliance standards such as ISO 9001:2015 need to be adhered to.

When considering how to display information clearly on products which will be exposed to harsh environments, manufacturers face a choice between using expensive metal rating plates (data plates) or using low cost computer imprintable durable labels.

Both options offer a durable identification solution, so why are so many people switching to computer imprintable durable labels?

Metal Rating Plates

Metal rating plates or ‘data plates’ are typically manufactured from anodized aluminum, ~1mm thick. Generally, these plates are extremely durable; withstanding abrasion, solvent exposure, weathering and extreme temperatures up to +932°F. In the right environment they can last a very long time and are exceptionally difficult to remove – particularly if they’re attached with screws or rivets. That being said, they have some limitations which depending on your industry, may be a deal breaker.

Anodization - limits the flexibility of data-printing

While anodization improves the lifetime of aluminum plates, it also severely limits the flexibility of data-printing.

The anodization process involves dissolving and oxidizing the top layer of the aluminum – essentially aging it artificially – which leaves microscopic pores on its surface. Pre-printed designs must be applied at this stage in order for the metal to accept the ink, as the plates are then sealed to prevent air or water getting into these pores and corroding the substrate.

This seal allows the embedded print to be almost as durable as the plate itself (think of a tattoo) but means that additional data must be physically engraved into its surface.

Engraving or etching metal plates

Regardless of the technology chosen, engraving and etching is a high-cost, time-intensive process. Engraving/etching also limits the ability to track and trace products using bar codes, even if you’re engraving tools are modern and capable of engraving in detail, scanners and imagers will not be able read the patterns. You could have your metal plate provider print black data at the point of manufacture and sealed to minimize fading however this can add significant expense and in many cases you may simply not be able to supply the variable data to your supplier in advance.

Color print can fade in UV sunlight

Not all color printed on metal plates is UV resistant. Some colors such as red, yellow and blue are particularly prone to fading and can be illegible within 6 months in conditions such as marine / offshore environments.

Metal Plates can corrode or degrade quickly

The effectiveness and durability of an aluminum plate is heavily dependent on the environmental conditions it is exposed to. For example, something as simple as salt water can corrode aluminum plates rending them useless as a long-term identification solution.

Time and cost of fixing metal plates

The time and costs involved in attaching, fixing, riveting and screwing metal plates can often come as an unwelcome surprise.

Printable rating plate labels

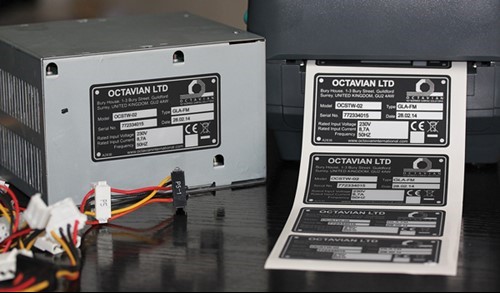

The development of high-performance computer imprintable labels has enabled manufacturers to provide the same information found on a metal plate in a much more efficient way.

Computer Printable, Low Cost and Easy to Customize

A key advantage of computer printable durable labels is that they are specifically designed to be easily printable and customized by the end user using a PC and laser or thermal transfer printer - removing the need to invest in expensive printing, etching or engraving equipment.

Durability – Lasting the life of the product

Durable printable rating plate labels are specifically constructed to last the lifetime of the product. Label constructions can be tailored to individual applications, surfaces and durability demands to resist; solvents and chemicals, weathering, abrasion, fuels and oils, extreme temperatures (-292°F to +730°F) etc., making them perfect for machinery, vehicles, components and much more.

Add value to your product with a professional label appearance

The appearance of a product can be improved by the addition of a well-designed computer printable durable label. Labels can be manufactured either blank or pre-printed with corporate logos/designs and made in any size or shape that you require for your product.

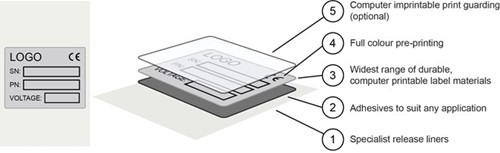

How a computer imprintable label is constructed

A computer printable durable rating plate label is typically constructed from 5 layers depending on the specifics of the application and its durability requirements.

- Specialist Release Liner carries the die-cut labels ready for the adhesive-backed label to be removed and placed onto a product.

- The Adhesive layer is what adheres to a product surface. For a permanent bond the correct adhesive must be carefully matched to the application’s surface type, surface temperature and environment. Typical adhesive options include; solvent acrylic, removable, void evident, tamper evident, water soluble, high-tack or heavy duty.

- Computer printable label material is another critical element which must be matched to the application. This is the layer upon which the variable data is printed. There are many options available, however for rating plate labels metalized or white polyester is a popular option due to its highly durable properties.

- Full color pre-printing includes corporate logo, text and symbols in any number of colors; ‘Print coated’ for durability.

- Computer Imprintable ‘print guarding’ is an option which provides extra durable protection of the pre-printed label design and is Laser or thermal transfer printable.

Cost Comparison

Metal Rating Plates

- High cost of metal plate

- High cost of engraving/etching + time

- High cost of tooling and drilling + time

- High cost of fixing (screws and rivets) + time

Printable Rating Plate Labels

- Low cost of labels

- Low cost of printing (minimal time)

Which is more durable and economical - metal plates or durable printable labels?

When you consider all the costs associated with sourcing and applying metal plates computer printable durable labels are more cost effective for industrial product identification.

Durable labels match or surpass metal plates in durability and are printable using a laser or thermal transfer printer, removing the need to invest in expensive equipment or outsourcing to an external supplier. In addition, printing labels ‘in-house’ gives greater production flexibility, avoiding delays and downtime waiting for external metal plate production.

However, matching the correct durable, computer printable label for a specific application environment can be confusing, therefore it is advised that you contact a technical labeling specialist to avoid purchasing an incorrect label solution.

Contact CILS for advice on how to switch to computer imprintable rating plate labels from metal or plastic plates. For rating plate label samples click here.