7 Tips to get the most from your Thermal Transfer Printer and labels in 2020

At CILS International, our technical support team are regularly contacted by customers with printer issues which are more often than not preventable with correct maintenance.

As a durable label manufacturer and printer supplier, we know a thing or two about getting the most out of your thermal transfer printer.

We have put together a list of 7 tips to ensure you achieve the best performance from your Thermal Transfer Printer.

1. Routinely vacuum the inside of the printer - this will remove any build-up of fibers/dust. Static caused by the friction of ribbon against print head can attract particles onto the ribbon which when passed under the print head can cause white ‘spots’ in the black print.

2. Keep the print head clean - if the print head is not regularly cleaned with a special print head cleaner (isopropanol pen) or cleaning cloth there can be a build-up of black residue over time caused by the friction of ribbon against the print head during printing.

This will be evident with vertical lateral stripes visible in black print. Set up a print head cleaning routine perhaps every time you change a ribbon or media roll.

If you don’t have a special print head cleaning pen, a cleaning cloth for thermal print heads or a cotton bud soaked with isopropanol alcohol (IPA) is perfectly good.

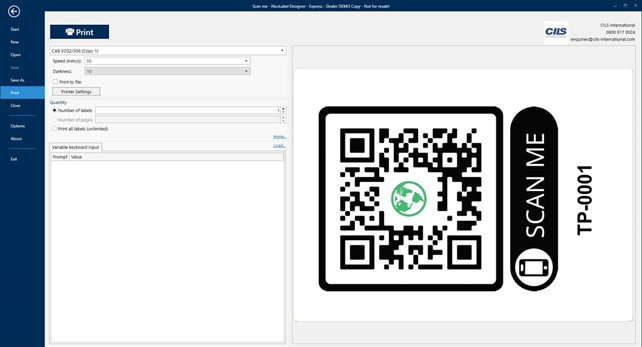

3. Use the correct heat and speed settings to get the best possible print quality and durability - When printing durable labels print on the slowest speed, lowest temperature setting and minimum head pressure to maximise the life of the print head.

The minimum of these three elements will be easy to see because you won’t have good quality print. Elevate the temperate while printing at the slowest speed until you have excellent print and durability.

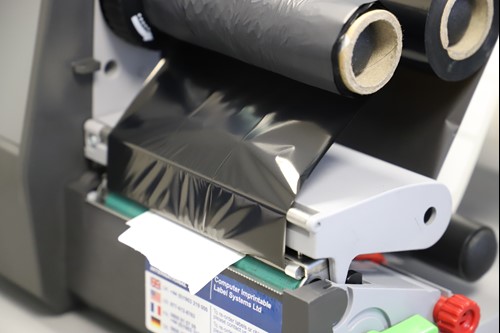

4. Avoid creases in the ribbon – make sure the cardboard core that collects the waste ribbon is perfectly aligned and completely smooth. Remove the waste ribbon regularly.

Diagonal creases can also be caused if the print head temperature (darkness) setting is too high. It momentarily snags on the heat and pressure of the print head.

Reduce the speed and head temperature to the lowest setting possible that still provides the print quality and durability you require.

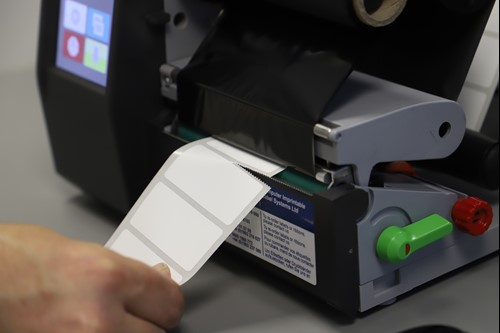

5. Use scissors or the printer’s tear bar to tear off the strip or roll of labels - do not use scalpels or knives as you may damage the drive roller which will cause voids in the print.

6. Ensure the printer is calibrated after installing a new ribbon or media roll – if you don’t calibrate your printer, you run the risk of wasting labels by printing in the wrong area (this often happens for smaller labels) or an error will appear (this is usually for larger labels).

It is worth noting, that some thermal transfer printers self-calibrate when the print head is closed, therefore it is recommended to find out this information before loading labels and attempting to print.

7. Use a slightly wider ribbon than the width of the label role - if you have a large label and try to use a ribbon with a narrower width that is only enough for the print area you need you run the risk of wearing the print head and drive roller unevenly.

Please note that print heads do wear out after a time and can easily be replaced. If you follow the advice above or have spoken with us and you still get vertical white stripes in your black print, it is most likely that the print head has become scratched or has worn out.

If you are looking to upgrade your existing thermal transfer printer, have issues with your current printer set-up or need assistance with choosing the label that is right for your application then we can help.

Our team of specialists are on hand to guide you through every step, making sure you get the right printer, ribbon and labels that are in-line with your requirements.

Why not consider part-printed labels meaning we print most of the label in-house but leave space for you to add your variable data yourself using your own printers.

We test all the printers we supply and our technical support team are available to assist you by phone, video link and remote access.

Talk to us about how we can help you with your printer and labelling needs.